I-Heat Shrink Skirt

Isicelo

1.Isetshenziselwa ukunqanyulwa kwamandla kagesi aphakathi kuze kufike ku-36kV

2.Khulisa ibanga le-creepage, uhlakaze imvula, ukusetshenziswa kwangaphandle kuphela

Isici

1.Ukungalandeleli

2.Ukumelana nokugqwala okuhle kakhulu

3.Ukumelana ne-UV nokumelana nesimo sezulu

4.Izakhiwo eziphezulu zikagesi nezemishini

Ukukhiqizwa kwamashubhu ancipha ukushisa kufanele kuqala kukhethe i-masterbatch efanele, bese ukhetha izinto ezisizayo ukuze kukhiqizwe okuthile.

Isikhwama sezindlu ezishisayo.

1. Inqubo yokukhiqiza ishubhu elincishiselwa ukushisa okokuqala iwukukhiqizwa kwe-polyene leech masterbatch: ukuhlanganisa izinto eziyisisekelo ze-polyene leech nezinto ezisiza ezihlukahlukene ezisebenzayo.

Izinto ezisetshenziswayo zikalwa ngokwesilinganiso sefomula bese zixutshwa: izinto ezixubile zifakwa ku-twin-screw extruder futhi zifakwe i-pellet ukuze kukhiqizwe i-polyene leech functional masterbatch.

2. Inqubo yokubumba umkhiqizo: ngokusho kokuma komkhiqizo, izindlela ezimbili ze-screw extrusion eyodwa kanye nokubunjwa komjovo zingasetshenziswa.

Okokucubungula nokukhiqiza:

1. Uhlobo lwe-screw extrusion: ikakhulukazi olusetshenziselwa ukubumba amapayipi osinki okushisa, njengamashubhu anodonga olulodwa ashwaqeka ukushisa, amashubhu anodonga oluphindwe kabili ashwaqeka ukushisa aneglue, nogqinsi olumaphakathi.

Amapayipi osinki okushisa odongeni, amapayipi okushisa okushisa aphezulu e-busbar, amapayipi okushisa anciphayo kanye neminye imikhiqizo konke kuyacutshungulwa futhi kwakhiwe ngesikulufu esisodwa.

Ulayini wokukhiqiza amashubhu oshwabene ukushisa kufanele ube nalezi zinsiza ezilandelayo: i-extruder (ukwakhiwa kweshubhu likasinki wokushisa), isikhunta sokukhiqiza, ithangi lamanzi okupholisa, idivayisi ye-tension, kanye

Idivayisi yediski, njll.

2. Ukubumba komjovo: okusetshenziselwa ikakhulukazi ukukhiqizwa kwezingxenye ezimise okukhethekile ezishwabenekayo, njengezikepisi zokucwilisa ukushisa, iziketi zezambulela ezishwabene zishwaqeka, ombhede weminwe oshwabenekayo neminye imikhiqizo.

Bonke basebenzisa ukubumba umjovo, futhi imishini yokukhiqiza kufanele ihlanganise nemishini yokubumba umjovo kanye nesikhunta sokujova.

3. Isinyathelo esilandelayo esibalulekile ukuxhumanisa ngemisebe.Imikhiqizo eyenziwe nge-extrusion noma ukubunjwa komjovo kuseyizinhlaka zamangqamuzana ezinomugqa.

Isakhiwo, umkhiqizo awukabi nawo "umsebenzi wenkumbulo", futhi ukusebenza kokumelana nezinga lokushisa, ukumelana nokuguga, nokumelana nokugqoka akwanele.

Shintsha ukwakheka kwamangqamuzana omkhiqizo.Indlela esivame ukuyisebenzisa ukuguqulwa kwe-radiation crosslinking: i-electron accelerator radiation crosslinking, i-cobalt source radiation.

I-cross-linking, i-peroxide chemical cross-linking, ngalesi sikhathi i-molecule iyashintsha isuka esakhiweni samangqamuzana ewumugqa ibe isakhiwo senethiwekhi.Imikhiqizo enwetshiwe iyadlula

Ngemuva kokuxhumanisa, "kunomphumela wenkumbulo", okuthuthukisa kakhulu ukumelana nezinga lokushisa, izakhiwo zemishini, kanye nezakhiwo zamakhemikhali zeshubhu elinciphisa ukushisa.Ithebula elithile

Manje ishubhu likasinki wokushisa selishintshile lisuka esimweni sokubekezelelana laya ekungahambelani, ukumelana nokuguga, ukumelana nokuhuzuka, kanye nokumelana nokugqwala kwamakhemikhali.

4. Ukubunjwa kokunwetshwa: Umkhiqizo olungiswe ngokuphambana kwemisebe usuvele “unomphumela wenkumbulo yomumo”, futhi unokuphakama okuphezulu.

Ukusebenza okungancibiliki ngaphansi kwezinga lokushisa.Ngemuva kokufudumeza ekushiseni okuphezulu, ukufutha kwe-vacuum nokupholisa, kuba yishubhu eliqediwe lokushisa elinciphayo, bese ngokusho kweshubhu.

Isimo sangempela sokupakishwa nokuvalwa komkhiqizo oqediwe nakho kungasikwa futhi kuphrintwe ngokwezidingo zamakhasimende.Ukupakisha okuvamile okumaphakathi nakho kuyatholakala.

Ukusebenza

| Hlola | Indlela Yokuhlola | Imfuneko |

| Amandla aqinile | I-ASTM D 2671 | ≥13 Mpa |

| Elongation ngesikhathi sekhefu | I-ASTM D 2671 | >400% |

| Amandla aqinile ngemva kokuguga kokushisa | I-ASTM D 2671/120℃,168h | ≥10 Mpa |

| Ukwandisa ngesikhathi sekhefu ngemva kokuguga kokushisa | I-ASTM D 2671/120℃,168h | ≥350% |

| Ukumelana nevolumu | IEC 93 | 1013Ω.cm |

| Ugesi ongashintshi | I-IEC 250 | 3.0 Ubukhulu |

| Amandla e-Dielectrical | I-IEC 243 | ≥15KV/mm |

| I-Copper corrosive 120 ° C, amahora angu-168 | I-ASTM D 2671 | Dlula |

| Ukuncipha kwe-longitudinal | I-ASTM D 2671 | 0 kuya ku-10% |

| Izinga lokumuncwa kwamanzi | ISO 62 | ≤0.1% |

| I-flame retadancy (inkomba ye-oxygen) | Idatha ye-ASTM4589 | ≥25 |

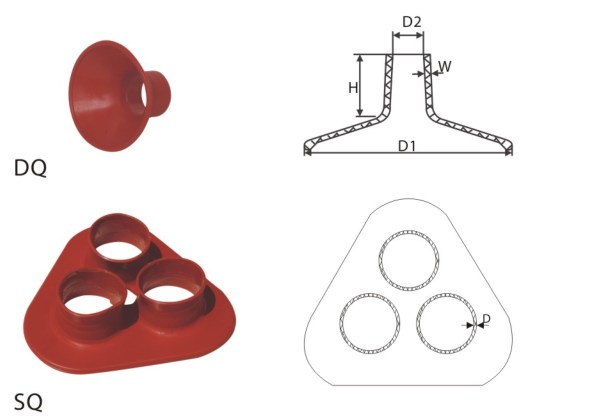

| Uhlobo | Kunwetshiwe (mm) | Itholiwe (mm) | |||

| D1 | D2 | I-D2 (ubuningi) | H | W | |

| I-DQ1 | 97 | 35 | 15 | 20 | 2.5 |

| I-DQ2 | 97 | 40 | 15 | 20 | 2.5 |

| I-DQ3 | 110 | 45 | 20 | 20 | 3 |

| I-DQ4 | 110 | 50 | 20 | 20 | 3 |

| I-DQ5 | 125 | 70 | 30 | 25 | 4 |

| Uhlobo | D | W | |

| Kunwetshiwe (mm) | Itholiwe (mm) | Itholiwe (mm) | |

| I-SQ1 | 32 | 12 | 3 |

| I-SQ2 | 38 | 15 | 3 |

| I-SQ3 | 45 | 22 | 3 |

UMBUZO: UNGASISIZA SITHUTHUKISE FUTHI SITHUNYEZELWE?

UMBUZO: UNGASISIZA SITHUTHUKISE FUTHI SITHUNYEZELWE?

A:Sizoba nethimba lochwepheshe elizokusebenzela.

UMBUZO:ZINI IZIQINISEKISO ONAZO?

A: Sinezitifiketi ze-ISO, CE, BV, SGS.

Q:SIPHI ISIKHATHI SAKHO SESIQINISEKISO?

A:1 unyaka uwonke.

Q: INGABE UNGAYENZA INKONZO ye-OEM?

A:Yebo singakwazi.

Q:YINI OHOLA ISIKHATHI?

A:Amamodeli ethu ajwayelekile asesitokweni, njengama-oda amakhulu, kuthatha cishe izinsuku eziyi-15.

UMBUZO: UNGANIKEZA AMASAMPELA AMAHHALA?

A:Yebo, sicela usithinte ukuze wazi inqubomgomo yesampula.