Iyini i-Socket Clevis?

I-Socket clevis yaziwa nangokuthi i-socket tongue iyingxenye ebaluleke kakhulu yobuchwepheshe be-pole line.

Ngokuvamile isetshenziswa kolayini abaphezulu, izintambo zokudlulisela, nezintambo zikagesi.

Kuyingxenye enkulu ku-pole line hardware evame ukuxhuma isivikelo sohlobo lwesokhethi kanye ne-tension clamp.

Bheka lokhu:

Ukuxhumana kwe-socket clevis kuyahlukahluka emazweni ahlukene kuye ngemithetho elawula ubuchwepheshe be-pole line.

Ngakho-ke, kubalulekile ukwazi ukuxhumana ezweni lakini ngaphambi kokuthatha isinqumo sokufaka i-oda lehadiwe.

Isibonelo, e-Afrika uhlobo lwe-socket clevis olusetshenziswa luhlanganisa:

Ulimi lwesokhethi lusetshenziswe ngokufanelekile kokuthi “I-Aluminium Conductor Steel Reinforced (ACSR)”.

Ububanzi bangaphandle buphakathi kuka-7 mm no-18.2mm (ama-square millimeters angu-25 kanye nama-square millimeters angu-150).

Iphinde yasetshenziswa "ku-standard disc insulators of ball and socket type" enobubanzi bephini lebhola le-16 mm.

Kungani Udinga I-Socket Clevis?

Njengengxenye ebalulekile ye-pole line hardware, i-socket clevis isetshenziselwa izinjongo ezithile.

- Ixhuma isivikelo sohlobo lwesokhethi kanye ne-tension clamp noma isekelo.

- Isetshenziswa njengokufanelekile ekuhlanganiseni ama-insulators ochungechunge olulodwa.Izibonelo zifaka “ibhola nesokhethi, i-clevis nokuxhumana kolimi, amapuleti ejoka wezivikeli ezinezintambo eziningi.”

- Ingasetshenziswa nasezintanjeni zikagesi njengesixhumanisi sikagesi.

- Emigqeni ephezulu, isetshenziswa njengengxenye ebalulekile yokuhlinzeka amandla kagesi ezitimeleni, kumabhasi ezinqola, kanye namathilamu.

- Kolayini bokudlulisela, iyingxenye yesistimu eklanyelwe ukusiza ekuqhubeni amanye amaza kumaza omsakazo.

Izingxenye Eziyinhloko ze-Socket Clevis

I-socket clevis ihlanganisa izingxenye nezingxenye ezihlukahlukene.

Nakuba zihluka ngemiklamo kanye nokuma, nazi ezinye zezingxenye ezivame kakhulu.

1. Amaketanga okusetshenzwa

Iwucezu lwensimbi ngokuvamile olumise u-U futhi luvikelwe ngephini le-clevis kanye nebhawodi.

Futhi, ingavikelwa kusetshenziswa iluphu yensimbi enamahinge enomshini wokukhiya okhishwa ngokushesha.

Isebenza njengesixhumanisi esiyinhloko kumasistimu ahlukene wokuxhumanisa njengoba enikeza ukuxhumana okusheshayo nokunqanyulwa.

2. Clevis pin

Iyingxenye ebalulekile ye-clevis fastener enezingxenye ezintathu eziyinhloko ezihlanganisa iphinikhodi ye-clevis, i-clevis, ne-tang.

Izikhonkwane ziyizinhlobo ezimbili ezihlanganisa ezingafundiwe nezifakwe imicu.

Izikhonkwane ezingafundiwe zinekhanda elimise okwedomu ekugcineni kanti ngakolunye uhlangothi, kunembobo ephambanayo.

Ukugcina iphinikhodi ye-clevis isendaweni, kusetshenziswa iphinikhodi ehlukanisayo noma iphinikhodi ye-cotter.

Iphinikhodi ecushiwe ngakolunye uhlangothi yenze amakhanda ngakolunye uhlangothi kuyilapho olunye uhlangothi lufakwe imicu nje.

I-nati lisiza lapho iphini kufanele libekwe endaweni.

3. Ibhawodi kaClevis

Ingasetshenziselwa ukwenza esikhundleni sephinikhodi ye-clevis nakuba ingathathi ukucindezeleka okusingathwa yi-clevis pin.

Zenziwa ukuthi zithathe futhi zigcine imithwalo yengcindezi.

4. Iphinikhodi kakhotha

Yaziwa nangokuthi iphinikhodi ehlukanisayo kuye ngezwe esetshenziswa kulo.

Khumbula, lolu ucezu lwensimbi olusebenza njengesibophelelo esineziphetho ezigobile ekufakweni.

Isetshenziswa ekuhlanganiseni izingcezu ezimbili zensimbi ndawonye.

5. Ibhawudi

Iwuhlobo lwesixhumi esinezintambo zangaphandle zesilisa ezisetshenzisiwe futhi ezinokufana nesikulufu.

Ngokuvamile isetshenziswa kanye namantongomane.

Ngakolunye uhlangothi kunekhanda lebhawodi kanti ngakolunye uhlangothi kunentambo yangaphandle yesilisa.

6. Nut

Lolu wuhlobo lwe-fastener enembobo enentambo.

Isetshenziswa kanye nebhawodi ukubopha noma ukuhlanganisa izingxenye ezihlukene ndawonye.

Ubambiswano luhlanganiswa nokuhlanganiswa kwemicu ngokusebenzisa ukungqubuzana.

Ngaphandle kwalokho, kuncike ekunwetshweni nasekucindezelweni kwezingxenye ezihlanganiswe ndawonye.

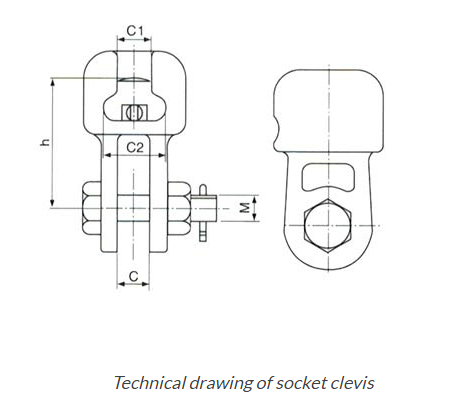

Ukucaciswa Kwezobuchwepheshe kwe-Socket Clevis

Ngaphambi kokuthenga i-socket clevis, kubalulekile ukunaka lezi zimpawu ezilandelayo ezibalulekile:

1. Uhlobo Lwempahla

Uhlobo lwezinto ezisetshenziswayo ekwenzeni ama-socket clevises yinsimbi nensimbi.

Lezi zinto zikhethwa ngoba zinamandla ngokwanele futhi zingakwazi ukumelana nesisindo nokucindezeleka.

2. Ukwelashwa Okungaphezulu

Ama-socket clevises adluliswa ngenqubo yokufaka i-dip galvanization eshisayo ukuze awenze amelane nokugqwala.

I-Hot dip galvanization ihlanganisa ukucwilisa insimbi noma i-clevis yensimbi ku-zinc ukuze uyipuletise futhi uyinikeze ukuthinta okubushelelezi kokugcina.

Insimbi nensimbi kugezwa ku-zinc encibilikisiwe ezingeni lokushisa elingu-449 degrees Celsius.

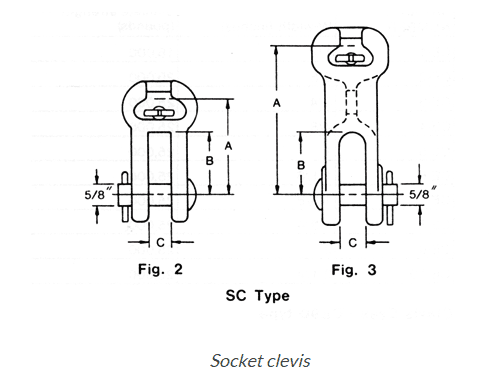

3. Ubukhulu

Ubukhulu be-socket clevis iyahlukahluka kuye ngosayizi wocingo.

Futhi, ubukhulu be-socket clevis buba bukhulu ubukhulu.

Ububanzi nobude kukalwa ngamamilimitha kuyilapho isisindo sinqunywa ngamakhilogremu.

4. Ukuklama

Umklamo osokhethini we-clevis uncike enkampanini ewukhiqizayo.

Ngokuvamile, ikhasimende linezwi ohlotsheni lomklamo elizowudinga kanye nomsebenzi elizowenza.

Umklamo we-socket clevis kufanele uhambisane nomsebenzi owawuhloselwe ukuwenza.

5. Umthwalo Okaliwe

Umthwalo olinganiselwe ku-clevis yesokhethi uncike kumthamo wamandla ezowaphatha.

Ikhasimende kufanele licacise umsebenzi ozokwenziwa yi-clevis ngaphambi kokuthenga i-clevis.

Umkhiqizi uzobe eseluleka nge-socket clevis efaneleke kakhulu mayelana nomthwalo olinganiselwe.

6. Isisindo

Isisindo se-clevis yesokhethi sincike kusayizi wedivayisi, impahla esetshenziswa ekwenzeni idivayisi.

Ezinye izinto ezisetshenziswayo zisinda kunezinye eziholela kumehluko omkhulu wesisindo.

Ubukhulu obufana nobubanzi, ubude buyahlukahluka kanjalo nesisindo.

I-Socket Clevis Manufacturing Process

Inqubo yokukhiqiza iqala ngokufudumeza, ukubumba, ukuthungatha bese kulandela ukugalela idiphu elishisayo.

Izinqubo ezibalulwe ngenhla ziyingozi futhi ngokuvamile ziyekele ukuze izimboni zisebenze.

Izinto zokwakha: impahla eluhlaza edingekayo insimbi kanye nesikhunta se-socket clevis.

Eminye imishini iyadingeka kule nqubo ebiza kakhulu.

Lesi yisizathu esenza ukuthi kushiyelwe izimboni ezinkulu ezifana neJingyoung ukuthi zikhiqize.

Isexwayiso: Inqubo yokwenza i-clevis ihilela ukuphatha insimbi emazingeni okushisa aphezulu kakhulu.

Kuyinqubo eyingozi futhi kufanele uqaphe kakhulu lapho ubamba insimbi encibilikisiwe.

Kufanele futhi ugqoke izingubo zokuzivikela namabhuzu ukuze uvikeleke kunoma yiziphi izingozi ezingase zenzeke.

Izilinganiso: Lena inqubo yokuthola osayizi abalungile bezinto ezizosetshenziswa ekukhiqizeni.

Kwenziwa ngokuya ngemininingwane yekhasimende uma kwenzeka kwenziwa ama-socket clevises enziwe ngokwezifiso.

Izinto ezisetshenziswayo zisikwa zibe izingcezu ezidingekayo ngaphambi kokuba zifakwe kwezinye izinqubo.

Inqubo Yokushisa: I-cast iron ishiswa emazingeni okushisa aphakeme kakhulu ukuze ikwazi ukuncibilika.

I-cast iron iyinto ekhethwa kakhulu ngoba incibilika emazingeni okushisa aphansi uma iqhathaniswa namanye.

Iguqulwa isuke ekubeni eqinile iye esimweni esiwuketshezi.

Insimbi encibilikisiwe ishisa kakhulu futhi kufanele kuqashelwe kakhulu phakathi nale nqubo.

Ngaphandle kokuncibilika okuphansi, i-cast iron ine-fluidity enhle, i-machinability enhle kakhulu, ukumelana nokugqoka kanye ne-deformation ukumelana.

Lezi zakhiwo ziyenza ibe yinto ethandwa kakhulu esetshenziswa ekwenzeni i-socket clevis.

Ukubumba: Insimbi encibilikisiwe ibe isithelwa esibunjeni se-socket clevis.

Isikhunta sakhiwe ngendlela yokuthi sibe nembobo efana nolimi lwesokhethi.

Insimbi ewuketshezi ithatha isimo sesikhunta esiwumumo we-socket clevis.

Anealing: Isinyathelo sesithathu i-anealing okuwuhlobo lokwelapha ukushisa okushintsha i-microstructure yensimbi.

Kuyinqubo eyenza i-socket clevis ifinyelele amandla ayo, ubulukhuni, kanye ne-ductility.

Ukupholisa: isinyathelo sesine sihilela ukushiya insimbi ebunjiwe ukuze iphole.

Inqubo yokupholisa iyaphuza ukuvumela isikhunta sihlale sisesimweni futhi singaqhekeki.

I-Hot dip galvanization inqubo yokugcina lapho i-iron epholile ithathwa ngayo.

Lokhu kuhlanganisa ukumboza i-socket clevis usebenzisa i-Zinc ukuyivikela ekugqwaleni.

I-socket clevis icwiliswa ku-zinc encibilikisiwe ezingeni lokushisa elingu-449 degrees Celsius.

Kuleli qophelo, i-clevis yesokhethi isilungile futhi iyahlolwa ukuze kuqinisekiswe ukuthi ilungele ukusetshenziswa.

Ungayifaka kanjani i-Socket Clevis?

Ukufakwa kwe-socket clevis kuyinqubo edinga ukuthi izigxobo zibekwe endaweni ngaphambi kokuzama ukufakwa.

Qinisekisa ukuthi zonke izinto ezisetshenziswayo zikhona futhi neladi likhona lokukukhuphula ufike endaweni ephakeme edingekayo.

- Izintambo ze-insulator kufanele zihlanganiswe phansi ngaphambi kokukhuphuka esigxotsheni.Ukuhlanganisa izintambo phansi kulula uma kuqhathaniswa nokwenza phezulu kwesigxobo.

- Ama-insulators kanye nezinto ezifakwayo nazo zifakwe phansi futhi nasezindaweni eziphakeme.

- Ukwandisa ukusebenza kahle kokufakwa, ikakhulukazi lapho izimo zokwakha zikhona, ukuhlanganiswa komhlabathi kukhethwa.

- Ukuhlangana ezindaweni eziphakeme kwenziwa lapho ukwakhiwa kunemingcele.

- Ngesikhathi sokufakwa kwama-insulators kanye nokufakwa ezindaweni eziphakeme, izisebenzi zithwala amathuluzi, izintambo namateyipu ensimbi phezulu kwesitebhisi.

- Isikhundla sokufakwa kwengalo yesiphambano siphawulwe futhi ngosizo lwentambo, idonswa.

- Ingalo yesiphambano ifakwe endaweni bese kufakwa ezinye ihadiwe ezifana ne-insulator nezintambo zokuvikela.

I-socket clevis iyingxenye ebaluleke kakhulu ye-hardware ye-pole line futhi ifakwe ochwepheshe.

Uhlobo lomsebenzi okulindeleke ukuthi iwenze ludinga abantu abanamava ukuthi bawufake njengoba amaphutha awamukelwa.

Kuyingozi kakhulu futhi ukuzama ukufaka ngaphandle kosizo lwabanye abantu okusho ukuthi ngeke kwenziwe umuntu ngamunye.

Isikhathi sokuthumela: Sep-17-2020